Introduction

The construction industry is constantly evolving to combat the various challenges of construction, and with the growing emphasis on innovation and sustainability, there is an increasing demand for innovative and eco-friendly building materials for quality and efficient construction. One such advancement is the use of interlocking bricks for construction. In this article, we will explore what interlocking bricks are, how they are manufactured, the different types of interlocking bricks, their advantages, and the challenges of interlocking bricks for construction.

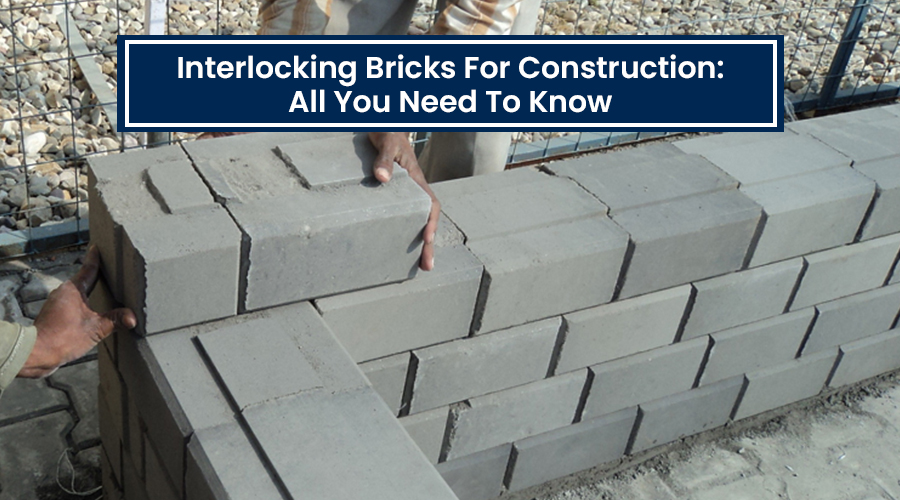

What are interlocking bricks?

Interlocking bricks are a type of clay brick designed to constructively lock together without the need for mortar. The bricks fit together like puzzle pieces to form a structure. This self-locking capability of interlocking bricks is attained by employing a shear key and lock mechanism. These bricks are typically made from a mixture of cement, sand, and stone dust. There are two main categories of interlocking bricks for construction: concrete interlocking bricks and soil interlocking bricks. Concrete interlocking bricks are made of cement, sand, and stone dust, while soil interlocking bricks are made of laterite soil and cement. These interlocking bricks have gained wide acceptance in construction due to their various characteristics and cost-effectiveness.

Interlocking Bricks Manufacturing Process

Interlocking bricks are manufactured through a precise process that involves mixing and compressing cement, sand, and stone dust in the right proportions.

The manufacturing process of interlocking bricks for construction typically involves the following steps:

- Batching and Mixing: The materials required for interlocking bricks, such as cement, sand, and stone dust, are measured and mixed in the appropriate ratio to ensure that the mixture is consistent and well-mixed.

- Compression: The prepared mix is then fed into a hydraulic compression machine, where it is compressed with a desirable interlock pattern to form interlocking bricks. The pressure applied during compression is crucial in creating the interlock mechanism that allows the bricks to fit together.

- Curing: The compressed bricks are stacked and left to cure for about a week. During this process, the cement in the mixture sets and bonds with the sand, creating stabilized interlocking bricks that are strong and durable.

Types of Interlocking Bricks

The various types of interlocking bricks are

- Interlocking Paving Bricks: These bricks are used for creating driveways, walkways, patios, and other outdoor paved surfaces. They are designed with interlocking features that create a durable and stable surface.

- Interlock Wall Bricks: These bricks are used for constructing walls, both for interior and exterior applications. They are designed with interlocking features that allow for easy assembly and provide structural stability.

- Interlocking Landscape Bricks: These bricks are specifically designed for landscaping purposes, such as creating garden borders, edging, and pathways. They are typically smaller in size and provide a visually appealing solution for landscaping projects.

- Interlocking Retaining Wall Bricks: These bricks are used for constructing retaining walls, which are designed to hold back soil and prevent erosion. They are designed with interlocking features that provide stability and strength to the retaining wall structure.

- Mud Interlocking Bricks: These bricks are made from natural materials such as clay, soil, and water and are typically used in low-cost housing and sustainable construction projects. They are eco-friendly and offer an affordable alternative for construction in rural and underdeveloped areas.

Advantages of Interlocking Bricks for Construction

- Require Less Water—Interlocking brick construction doesn’t require much water like the conventional way of construction, as interlocking bricks interlock each other efficiently.

- No plaster required—interlocking bricks have a smooth finish and do not require plastering, saving time and labor costs. The interlocking design also ensures a tight fit between the bricks, eliminating the need for mortar or adhesive, further reducing construction time and costs.

- Cost-effective: Interlocking bricks are often cost-effective, as they require less material and labor during construction. The reduced need for mortar or plastering post-construction thus lowers construction costs.

- Eco-Friendly: Interlocking bricks are made from natural materials such as cement, sand, and stone dust, making them environmentally friendly. They do not require burning or firing like traditional bricks, which reduces the carbon footprint and air pollution.

- Better Insulation in Hot Climates Interlocking bricks are less heat-intensive in nature and keep the room cool, making them an ideal choice for construction in hot climate areas.

- Quick Construction—The interlocking design of these bricks allows fast and efficient construction, as they require approximately 7 days of curing after construction, resulting in quicker construction timelines and cost savings.

- Earthquake Resistant—Unlike conventional bricks, interlocking bricks can distribute the seismic force across the structure due to their interlocking pattern, thus preventing the structure from collapsing.

- Easy to Dismantle—Interlocking bricks can be dismantled with little damage and reused, making them an excellent sustainable choice. This feature allows for flexibility in construction and reduces construction waste, contributing to a more sustainable construction practice.

Challenges of Interlocking Bricks:

Despite their many advantages, interlocking bricks for construction do have some drawbacks. Some of the disadvantages of interlocking bricks are

- Interlocking bricks are not advisable to use in high-story buildings or buildings with more than two stories.

- The gap between the interlocking can become a breeding ground for insects.

- These bricks are not suitable for custom designs.

- There is a high chance of rainwater penetrating the gap between the bricks if no plastering is done

- They are not suitable for use in frequent wet areas like bathrooms or for drainage

Conclusion:

Interlocking bricks for construction have emerged as a promising innovation in the construction industry. These bricks are manufactured through a precise process involving batching, mixing, compression, and curing. There are various types of interlocking bricks, such as paving bricks, wall bricks, landscape bricks, and retaining wall bricks, catering to different construction needs.

Interlocking brick offers numerous advantages, such as reduced water usage, no plastering requirement, cost-effectiveness, eco-friendliness, better insulation in hot climates, quick construction, earthquake resistance, and easy dismantling. However, there are also challenges of interlocking bricks, such as limitations in high-rise buildings, potential breeding grounds for insects, limited custom designs, and the limitation of being used for wet areas. Despite these challenges, the advantages of interlocking bricks make them a viable and sustainable option for modern construction, contributing to eco-friendly and efficient building practices. As the construction industry continues to evolve, interlocking bricks are likely to gain further prominence as a preferred choice for innovative and sustainable construction solutions.