Erosion, broken pebbles, and rock weathering produce sand that is carried by waves and rivers. The sand will be unsettled by freezing and thawing over the winter season.

Sand is one of the most significant components in building a robust and long-lasting structure. In the construction of any building, several types of sand and gravel are used extensively.

The sand is impossible to classify. Because sand is a highly diverse substance, it is possible to divide it into distinct types.

Here is a guide to the types of sand that are used in the construction field.

8 Types of Sand

Pit Sand

This is gritty sand that is typically reddish-orange in hue. Deep holes sunk 1 to 2 meters below the topsoil provide security. Pit sand grains are rough, angular, sharp, and abrasive. It is a traditional choice for concreting since it is free of salts and other contaminants.

River Sand

River bottoms and banks are where you’ll find it. Due to the rubbing action of water currents, they are fine, spherical, and polished. Because of its roundness, it has a lower frictional strength. The color is almost white. Because grains are smaller than pit sand, they are better for plastering.

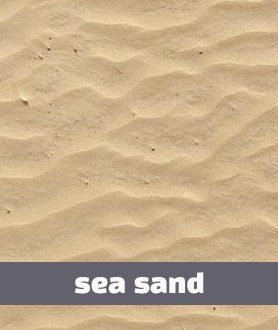

Sea Sand

Sea sand grains are exceedingly fine in quality and have a round shape. Sea sand is made up of salt and other marine pollutants that absorb moisture from the air and release it as moisture. As a result, it’s only utilized in tiny portions in concrete structures and industrial processes.

Manufactured Sand

Manufactured sand is an artificially formed sort of sand that is used as an alternative to river sand in building. It is made by crushing hard granite stones. It is created with the desired fineness, shape, surface smoothness, texture, and consistency, making it the best sand for construction while reducing segregation, bleeding, honeycombing, voids, and capillary.

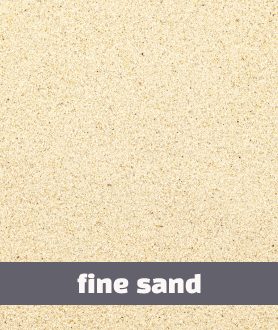

Fine Sand

Fine sand is the most common sand used in plastering walls because it provides a high-quality finish to each corner of a home internally. Its small granules smooth and strengthen the walls from the inside out. As a result, it retains wall colors for longer periods. On the other hand, fine sand is combined with coarse sand to strengthen the walls and support the weight of large structures.

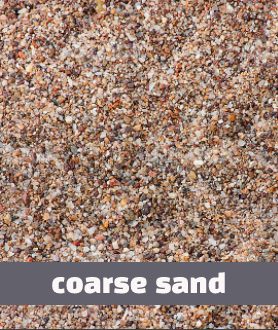

Coarse Sand

Coarse sand is the most prevalent type of sand used in building construction in India. Large concrete buildings can be easily formed by mixing them with water, aggregate, and even cement. Coarse sand is good for bedding pipelines and sewage systems, as a base material for concrete slabs or pavers, as traction sand for roads and sidewalks, and as a top dressing material for seeding grass when mixed with topsoil and mulch.

Utility Sand

It’s construction-related sand made from high-quality industrial quads. It is a branded construction material due to its superior compaction quality and improved mechanical properties. It can also be utilized in harsh situations because it is resistant to corrosion. The presence of 100 percent natural minerals in its homogeneous grain shape ensures the building’s long-term stability and durability.

Fill Sand

This type of sand is primarily used for filling, as the name implies. It is a mixture of sand grains and aggregates that are used as a principal base material for laying concrete, filling huge gaps, and paving, among other things. Its essential virtue of displaying compassion makes it an unsurpassed building material.

Types of Sand for Construction

Concrete sand, pit sand, natural or river sand, manufactured sand (M-sand), utility sand, and fill sand are the most common forms of sand used in construction. These sands have distinct qualities that make them appropriate for a variety of construction projects.

Greensand and dry sand are the two most common forms of sand used in molding. Silica sand, clay, moisture, and other ingredients make up green sand. Dry sand is a sand-and-quick-curing-adhesive mixture. “No-bake mold casting” or “air-set sand casting” are terms used when dry sand is applied.