One of the most significant components of a property is the roof. Different types of roofing sheets come packaged with their own set of uses. The roof has evolved in lockstep with the design of a house over time. The roofing material, which began as clay, eventually evolved into shingles, which have become a widely used roofing material in India and around the world.

People were looking for an alternative roofing solution to provide a protective covering to their homes with greater aesthetics and durability due to the limitations of roofing shingles, which led to the introduction of steel roofing sheets.

In the last decade, the Indian roofing business has undergone a fundamental transformation. There are two main reasons for the changes in the roofing sheet sector. One, about the Indian market, there has been an increase in industrial uses. Second, consumers are dissatisfied with the standard solutions provided and want more value from their roofing sheet purchases.

As a result, the need for various types of sheets to protect the roofs and walls of establishments—domestic, commercial, and industrial—has increased.

Here’s a quick review of the most common types of roofing sheets

Let’s have a look at the different types of roofing sheets that are utilized in buildings.

- Corrugated

- Galvanized Steel Sheet

- Polyester Painted Sheets

- PVC Plastisol

- Bitumen

- Sheet Metal

- Polycarbonate

- Plastic

Different types of roofing sheets in India

- AC Roofing Sheets

Asbestos cement sheet is made using asbestos fiber mixed with the cement during the manufacturing process. Asbestos gives the sheet body firmness and rigidity, allowing it to keep its size without breaking. When inhaled for an extended period, the fibers can cause diseases such as lung cancer, mesothelioma, and asbestosis.

Asbestos has been outlawed in numerous countries due to health concerns; plant fibers are gradually taking its place.

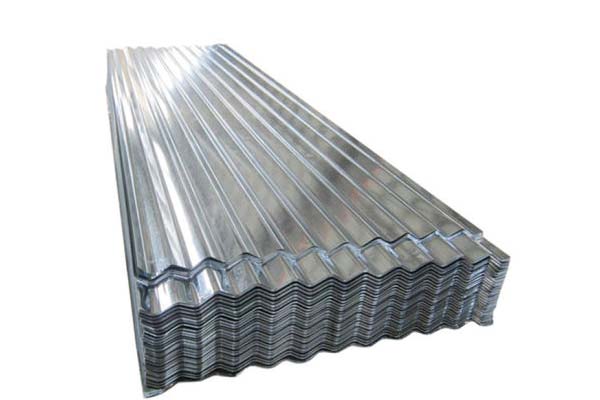

- Corrugated Roofing Sheets

Because of its shape, corrugated roofing is extremely durable. Because the screws for fastening penetrate through the peak of the ribs, these sheets require the support strips to stabilize the material. The ribs and valleys’ curvature inhibits the screws from properly sealing in the valleys.

- Metal Roofing Sheets

Metal roofing sheets are a popular choice because of their excellent insulation capabilities. Zinc, aluminum, copper, and tin are used to make them. Metal roofing has a lot of benefits, including the capacity to endure almost any type of weather. Metal roofing is available in a variety of colors and textures, giving the appearance of natural cedar shakes or stone. It is more fire-resistant and can weather a storm without being damaged. Garden structures, garages, home cladding, and industrial roofs can all benefit from these sheets.

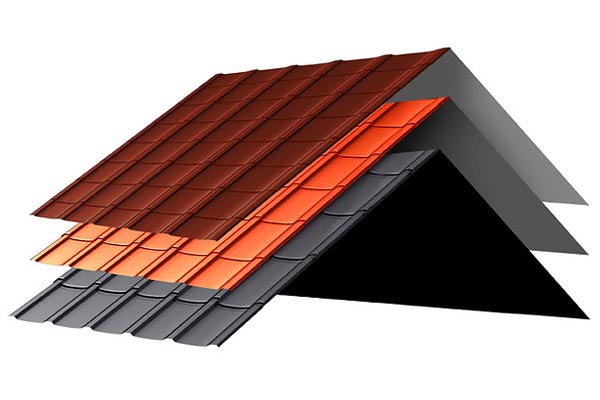

- Cladding Metal Roofing Sheet

Cladding metal sheet roofing functions as a covering construction material with a protective layer, providing several practical and aesthetic benefits. They’re made of either aluminum or steel. These roofing sheets protect the inside building materials from the elements and improve the structure’s mechanical stability.

- Aluminum Roofing Sheet

Aluminum sheets’ key benefit is their excellent strength-to-weight ratio. The lightweight reduces the dead load on the structures, allowing for thinner supporting structures and lower total costs. Their anti-corrosive characteristics help them to last longer and keep their lustrous appearance. These sheets are a good choice as they can be easily installed and demand very little maintenance.

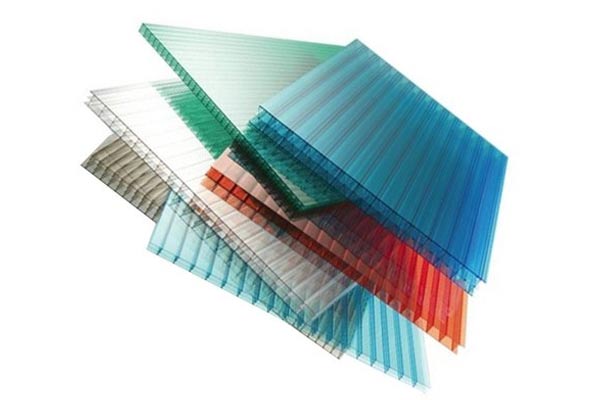

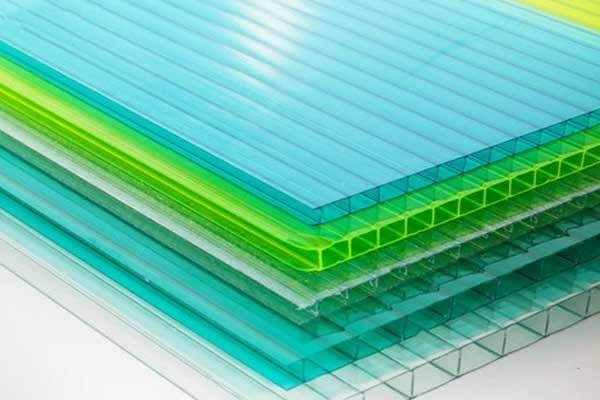

- Polycarbonate Roofing Sheet

Polycarbonate is a thermoplastic that is amorphous and contains carbonate groups in its chemical composition. They are translucent and low in weight. Because of their transparency, the sheets can be used in spaces that require a lot of light, such as patios, greenhouses, warehouses, and carports. The primary downside of this roofing sheet is its high price, which limits its application.

- FRP Roofing Sheet

Fiber-reinforced plastic (FRP) is a thermosetting resin and fiber composite material. Fiber serves as a reinforcement material, in this case, providing rigidity and helping to keep the molded shape. Roofing sheets come in a range of colors and styles and can be flat or corrugated.

- PVC Roofing Sheet

Polyvinyl chloride (PVC) is a thermoplastic polymer made from the vinyl chloride monomer after it has been polymerized. PVC roofing sheets are more popular than other types of sheets because they are weather-resistant, non-corrosive, lightweight, and waterproof.

- UPVC Roofing Sheet

Unplasticized polyvinyl chloride (UPVC) is a type of polyvinyl chloride. When no plasticizers are added to PVC material, the result is UPVC, which is a hard and inflexible polymer plastic. These sheets are hard and inflexible, with no elasticity, and their usefulness differs from that of PVC sheets.

- Plastic Roofing Sheet

Polypropylene, polyethylene, PET, and other plastics have been referred to as such in this article since that is how the general public refers to them. These plastic roofing sheets have a specific application in light structural buildings. They’re light, corrosion-resistant, flexible, and waterproof.

- Color-Coated Roofing Sheet

The galvalume (typically 55 percent aluminum, 43 percent zinc, and 1.5 percent silicon) was blended with high-quality colors that met precise specifications to coat steel and other alloy sheets (surface treatment). The coating has a royal appearance and also has anti-corrosive properties. As illustrated in fig. 1, they are available in single-colored or multicolored patterns.

- GI Roofing Sheet

Iron or steel sheets were galvanized with zinc or zinc + aluminum to acquire anti-corrosive qualities in these sorts of sheets. The most prevalent surface treatment methods are hot-dip galvanizing and electro-galvanizing. They come in a variety of sizes and gauge thicknesses to suit your needs.

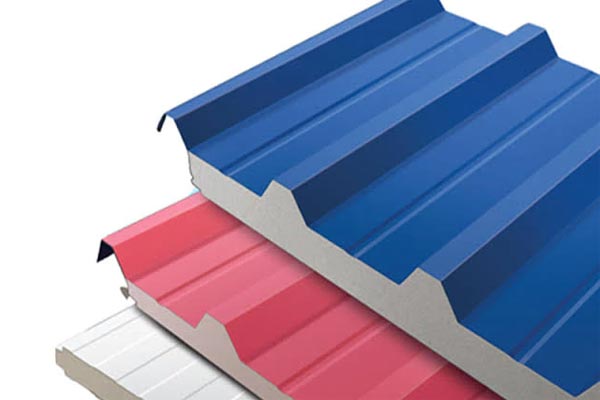

- PUF Roofing Sheet

Polyurethane foam (PUF) is a type of polyurethane foam. Between two sheets of identical material and dimension, the foams are sandwiched. These sheets are utilized in applications where thermal insulation is important.

- Rubber Roofing Sheet

They are a waterproof and heat-resistant secondary roofing material that is clad over the current roofing system. To achieve a single frame, EPDM (ethylene propylene diene monomer) rubber is wrapped over the surface and attached or taped with the specified binding material.

- Bio-composite Roofing Sheet

Plant fiber was used as a reinforcement ingredient in the synthetic resins used to make these roofing sheets. Sisal fiber, jute fiber, banana fiber, coconut coir, and other fiber materials are often utilized in the manufacturing process. They are environmentally friendly and give the structure a more cultural appearance.

- Bitumen Roofing Sheet

These roofing sheets are suitable for use in both cold and hot climates. The biggest downside is that it absorbs heat from the sun, causing the building to heat up.

- Bamboo Roofing Sheet

These sheets give the roofed structure an antique and traditional appearance. Resins were applied to the corrugated bamboo sheets to protect them from the elements.

Check out more: Grip Yourself with every little thing about TMT Steel