Sand is a granular material that is composed of finely divided rock and mineral particles. It’s outlined by size and is finer than gravel and coarser than silt. Sand may also be referred to as a textural category of soil. The textural category of soil contains over eighty-five % of sand-sized particles by mass.

WHAT IS SAND MADE OF

TYPES OF SAND

WHAT IS SAND PLANT

USES OF SAND

WHAT IS SAND MADE OF

Sand is the conclusion of the many things, together with rotten rocks, organic by-products, and even percoidean poop.

The meliorist biologist wrote, “In each curvilineal beach, in each grain of sand, there’s a story of the world.”

Sand comes from several locations, sources, and environments. Sand forms once rocks break down from weathering and wearing over thousands and even various years. Rocks take plenty of time to decompose, particularly quartz (silica) and spar.

Starting then covering thousands of miles from the ocean, rocks slowly travel down rivers and streams, perpetually breaking down in the process. Once they are created, in to the ocean, where they are additionally eroded by the constant action of waves and tides.

The tan colour of most sand beaches is the result of an iron chemical compound that tints quartz a light brown, and spar, which is brown to tan in its original state. Black sand comes from scoured volcanic material like volcanic rock, volcanic rock rocks, and different dark-coloured rocks and minerals, and is often found on beaches close to volcanic activity. Black-sand beaches are common in Hawaii, the Canaries, and the Aleutians.

The by-products of living things additionally play a crucial role in making sandy beaches. Bermuda’s preponderance of pleasantly pink beaches results from the perpetual decay of cellular, shelled organisms known as the order Foraminifera.

TYPES OF SAND

6 types of sand used in construction:

1. Concrete Sand

Concrete sand is one of the categories of sands in India that is made of crushed concrete. It’s a typical element of cement and asphalt mixtures. This sand is crushed within the quarry and filtered to get rid of the big rocks and big fragments. It’s a kind of coarse sand that may be mixed with cement and water and used as a level base layer for patios and walking paths. Once mixed with cement and water, it forms a solid mass that’s used to fill the voids between the coarse aggregates. It’s smaller-grained compared to crushed stone sand and hence is often used to construct softer pavements.

However, it’s additionally larger than white sand and hence is often used as a filling material too. The dimensions and texture of this sand make it a perfect material for lots of functions. It provides basic stability to a building.

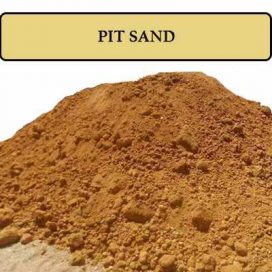

2. Pit Sand

Pit sand is a kind of sand that’s best used in the construction of buildings because of its superior binding property. It’s coarse sand that’s found 2-3 meters underneath the bottom. It’s obtained naturally from deep pits. It consists of rough, sharp, angular, and coarse grains that give glorious binding properties.

Their color is red-orange because of the presence of iron oxide. The grains of this construction sand are free from salts, and thence they do not simply react with the moisture present within the atmosphere. Because of this property, they supply powerful and rigid buildings.

3. Stream Sand or Natural Sand

River sand is a fine quality of construction sand that’s found close to stream banks and streams. This sand is white-grey and is one of the fine hierarchic sands utilized in the development of buildings. They’re chiefly utilized in concrete and masonry work. They’ll even be used for RCC, covering, or block works. This sand consists of a swish texture and a much better form of grains. The stream or natural sand demands less water. The wetness that is trapped between these sand particles serves a sensible purpose for concrete functions. A medium quality stream sand consists of five to twenty percent silt content.

Since stream sand is obtained on its own, hence is cheaper. These styles of sand contain oxide content. Therefore, it’s necessary to envision the quantity of oxide content and ensure that it’s below 5% before utilizing it for construction.

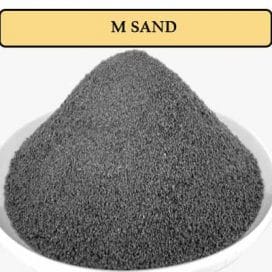

4. M – Sand

M-sand stands for factory-made sand and is one of the widely used sands for construction in Asian nations. This sort of construction sand is factory-made within the factory. It will be used as a substitute for watercourse sand for concrete construction. Factory-made sand has been used ever since the demand for high-quality sand has increased rapidly. This sort of construction sand is made ready by crushing hard granite, and thus it reduces the transportation costs of transporting sand from watercourse beds. It contains particles of an angular nature that will increase the strength of concrete. These angular particles within the sand will increase its water demand. This water demand will be remunerated by adding cement content. Since it’s unnaturally factory-made, it contains zero silt content. There aren’t any outsized materials found in these kinds of construction sand.

This is a kind of construction sand that’s simply accessible too. Since it is factory-made and not natural, it will be free from any impurities, and also the sizes of the sand grains will be controlled as desired, which suits every purpose. Since they’re factory-made in very controlled surroundings, there’s little or no chance of adulteration of this sand, and there’s higher management over the producing quality of the M-sand. The M-sand provides smart sturdiness and imparts high strength to concrete. It’s economical and reduces construction defects.

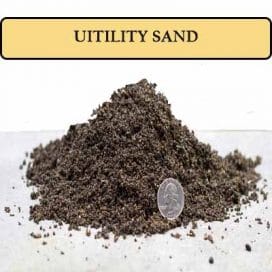

5. Utility Sand

Utility sand could be a type of sand utilized in construction. This sort of sand is created from top-quality industrial quartz. This sort of construction sand provides glorious compaction and smart mechanical properties because of its uniform grain shapes. It will be utilized in corrosive environments since it’s non-reactive. They contain 100% natural minerals, which offer glorious sturdiness and stability to the building.

6. Fill Sand

The Fill sand could be a style of sand utilized in construction, usually for filling. It’s a mixture of many grains of sand and aggregates. It consists of terribly fine rock particles that are lessened and undergo erosion. It will be primarily used as a base material for laying concrete, paving, and filling giant holes. Its glorious compaction makes it the right base material for many functions throughout the development of a building. It provides tons of benefits once utilized in wet areas to mend evacuation issues by serving as a backfill around septic tanks.

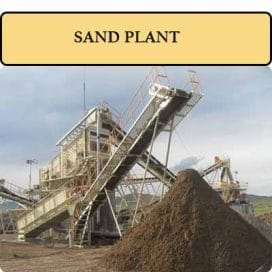

WHAT IS SAND PLANT

The sand plant produces the crushed sand as an alternative to stream sand. We’ve got a special sand creating machine like a VSI device, sand screening machine like a vibratory screen. These sand crushing and screening instrumentation square measure for maximum productivity. Sand Plant Manufacturer additionally offers individual crushers and screens, as well as key parts and carrying elements.

Sand creating plant includes quartz sand creating the assembly line, building sand creating assembly line, and stone material assembly line, all of which may turn out aggregates and crushed sand from sedimentary rock, granite, volcanic rock, and stream stone. All Sand Plants products square measure wide utilized in the development of hydraulic power stations, artifacts, highways, and concrete infrastructure.

The sand plant operates as follows:

Firstly, the materials are fed into, the primary device for primary crushing. Then the materials are transferred by the belt conveyor to the secondary device for further crushing. Then the vibratory screen is used to grade the materials, wherever the requirement is filled material is sent to the sand-maker, whereas the remainder comes back for an additional spherical of crushing. A part of the stones processed by the VSI device is created into the sand and becomes a sand product when being washed. The remaining are crushed by the sand maker into qualified sand materials of various varieties.

USES OF SAND

Followings are the common sand uses.

- We will use sand to filter water; it works like an abrasive.

- We will use sand to relinquish a position to our painting or wall art by combining a pair of cups of paint with a ¾ cup of sand.

- People build sandpaper by gluing sand to paper.

- While bunging metal, we will combine sand with clay binder for frameworks utilized in the foundries.

- Sand may be used for cleaning up oil leaks or any spill by dredging the sand over thereon spill. The fabric can type clumps by absorbing, and we will quickly clean the mess.

- Sand may be used as a road base that may be a protecting layer beneath all roads

- Industrial sand is employed to create glass, as manufacturing plant sand, and as abrasive sand.

- One artistic usage of sand is serving as a holder. We will attempt to swing some sand before running a tea light or any candle in an open glass. It holds the candle still and prevents the candle from rolling by giving it a superb decoration.

- Adds texture and aesthetic attractiveness to the house.

- Sand is usually pure to handle and economically wise.

- We will build a children’s pit to make the play areas safer. It’s quite cheap, furthermore.

- Sand is also used in aquariums, fabricating artificial fringing reefs, and in human-made beaches.

- Sandy soils are ideal for growing crops, fruits and vegetables like wa,termelon, peaches, peanuts, etc.

- Sand will light a path by filling mason jars with sand and tea lightss, which is another cheap way to build a path glow.

- We will keep a little scuttle of sand close to a charcoal grill for extinguishing flare-ups.

- Sand may be used for cleansing the slim neck receptacle by swinging a sand and heat cleanser water within the instrumentation.

- We will keep an item steady that requires repairing by victimization sand.

- Sand helps to enhance resistance (and so traffic safety) in icy or snowy conditions.

- We want sand within the beaches wherever tides, storms, or any style of creating mental changes to the bound crumble the primary sand.

- Sand containing oxide is employed for creating shut-in the car and food industry, even home merchandise for the room.

- Sand may be a sturdy strand that is employed for plaster, mortar, concrete, and asphalt.

- The usual bricks made of clay are much weaker and lighter in weight than blocks product of clay mixed with sand

SUMMARY

Sand is a mixture of little grains of rock and granular materials that is especially characterized by size, being finer than gravel and coarser than silt. And ranges in size from 0.06 metric linear units to a pair of metric linear units. Particles that are larger than 0.0078125 metric linear units and are smaller than 0.0625 metric linear unit area units are termed silt.

Read More: Be Informed About Different Types of Sand Used in Construction