Concrete was created more than 2,000 years ago and has continued to be one of the most widely used building materials. It is affordable, sturdy, long-lasting, simple to mass-produce, and simple to maintain. The negative? Concrete is prone to cracks that might jeopardize a building’s overall structural integrity. Cracks can cause destructive damage if they are not found and repaired when they are still small.

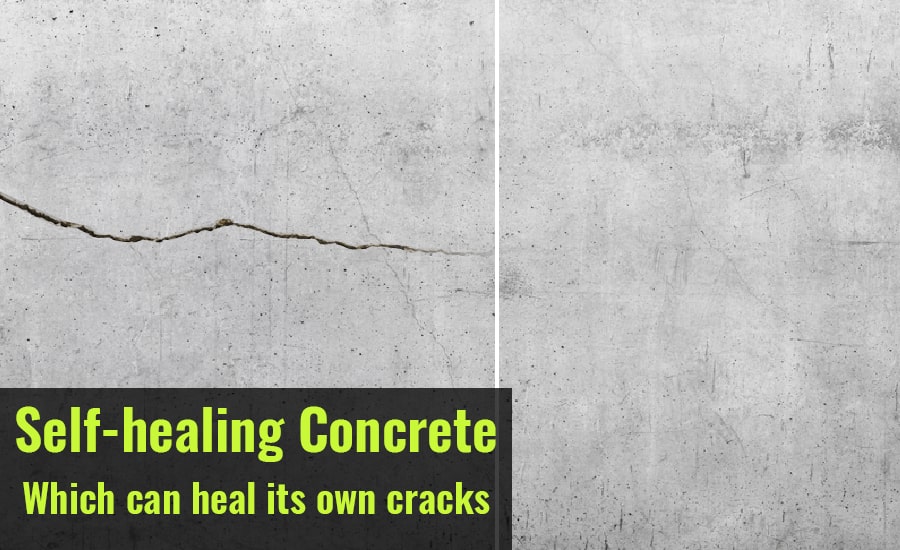

Because concrete has a relatively low tensile strength, cracks are a regular occurrence. Concrete that can cure cracks is generally referred to as having self-healing properties. Another name for it is self-repairing concrete.

Settlement, expansion, plastic shrinkage, shear, and flexural cracks are common cracks in concrete. Cracks are caused by reinforcing corrosion, defective design, thermal stress, and weather-related cracks.

But it appears that the era of fractured concrete is coming to an end. By creating self-healing concrete, scientists have transformed the industry.

Crack formations can occur for a variety of reasons. However, to name a few:

- Improper vibration, mixing, and curing.

- The use of high loads.

- The utilization of low-quality materials (such as reinforcements susceptible to corrosion)

- Adverse effects of temperature

- Faulty mix design

- Large amounts of water in improper concrete water-to-cement. Ratio maintenance

So, what can be done to assist in resolving the problem? Let’s conduct a quick investigation into this.

Methods of Self-healing In Concrete

Autogenous Self-healing Concrete

Certain autogenous healing qualities are organically processed by concrete itself. The healing process is started by the hydration of the clinkers’ minerals. Unhydrated cement particles serve as a therapeutic substance in this technique.

Ca²⁺ + 3H₂O + CO₂ → CaCO₃ + 2H₃O⁺ + 2OH⁻

Due to the inherent characteristics of concrete and the breakdown of calcium, this reaction of cement with water helps repair hairline fractures.

Autonomous Self-healing Concrete

Although autogenous self-healing is inherent, it can only be used to repair minor fissures. Autonomous self-healing techniques are effective in this situation. Additional exterior self-healing provisions are accommodated here for enhanced performance and concrete repair.

Vascular self-healing method

Vascular self-healing is a multiple healing approach in which a network of hollow tubes containing a healing ingredient is placed in concrete. It is important to keep in mind that the tubes are chemically inert when picking them. Additionally, the concrete and these long parallel tubes need to be secured well.

Inorganic phosphate cement (IPC) is highly recommended, along with clay tubes. When a healing agent comes into contact with a crack in the concrete, the crack is sealed by hydrostatic pressures, capillary forces, and gravitational forces.

Capsule-based Self-healing method

This approach uses a microcapsule that can be either cylindrical or spherical. Silica, ceramics, glass, polystyrene, and urea-formaldehyde are all acceptable materials for the shell. The cementitious matrix and the characteristics of the inserted capsules determine how effectively this approach heals.

You can rely on multi-capsule systems as well. These capsules split open when they come into contact with one another, releasing healing agents that fix the fracture. Epoxy resins, polyurethane, or methyl methacrylate monomers are examples of healing agents (MMA).

Embedding shape memory alloys (SMAs) method

Form Memory Alloys are a type of intelligent material that can be utilized in concrete because they have the unusual ability to regain their original shape even after being deformed. They essentially serve the purpose of self-centering.

Researchers have looked into the results of heating shape memory alloy wires with electrical currents and injecting the heated wires into concrete beams. The shape memory alloys were used for retrofitting; they received a pre-tension before testing. The mid-span was loaded during the test cycles, and deformation and cracking were examined. The heated wires successfully repaired the cracks and sealed them.

Microbial or Bacterial Self-healing Concrete

Calcium carbonate (CaCO₃) repairs concrete microcracks through precipitation using a microbial/bacterial self-healing technique. Batch production of microbial spores and calcium supplements, including healing agents, is followed by incorporation into concrete. Researchers have tracked microbial concrete incursion, for instance, in the side walls of a ship lock and seen the fissures mend in about 60 days.

Advantages of Self-Healing Concrete

The primary benefit of self-healing concrete is this. Years or even millennia can pass before it. This guarantees that during the duration of your concrete surface, we won’t ever need to replace it.

Concrete maintenance is reduced with self-healing concrete.

Cracks in typical concrete must be filled and sealed. But with self-healing concrete, the compressive strength of the concrete has improved, so you don’t have to do this or worry about it.

Disadvantages of Self-Healing Concrete

The cost is now one of its main drawbacks. When compared to regular concrete, it is pricey. When self-healing concrete is widely used in the future, prices might go down. It is now relatively uncommon.

Not many contractors are yet proficient in using this tool. Since it is a new product, many individuals are unsure how to utilize it. The self-healing concrete cannot be standardized because no code exists.

The way we construct and plan our infrastructure is once again being revolutionized by one of the most widely used building materials. Because of self-healing concrete, wear and tear won’t be an issue for concrete buildings or sidewalks. Self-healing concrete is still being developed, but scientists are employing various strategies. These therapeutic substances were developed using fungi, sodium silicate, and microorganisms.

Check Our Latest Blog About Light-Emitting Cement