Introduction

The construction industry has always been known for its traditional methods of building structures, but in recent years, with the advancement of technology, new ways of construction have emerged. One of the latest trends in the construction industry is the use of 3D printing technology, which has the potential to revolutionize the entire sector. From building mansions to offices to homes, 3D printing is increasingly adopted in the construction world. In this article, we will explore what 3D printing in construction is, how it works, what the advantages and challenges are, and the possible scope of 3D printing in the future.

What is 3D Printing in Construction?

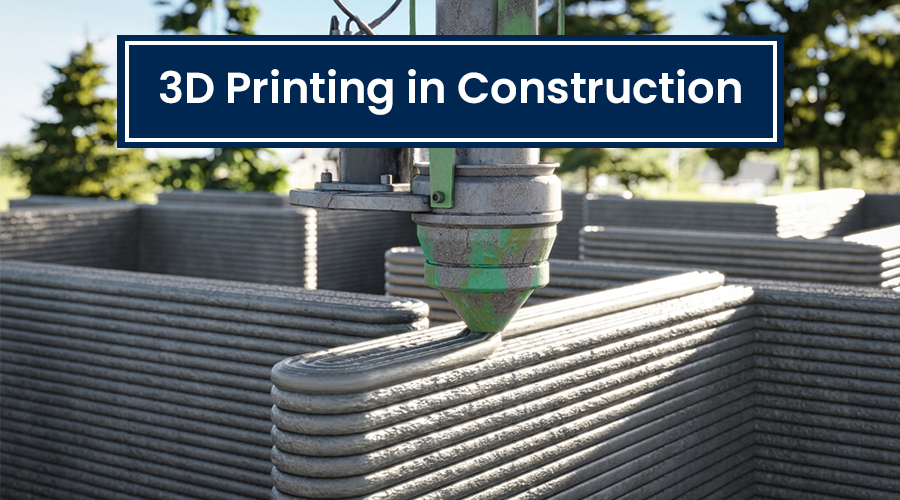

3D printing is a process of creating three-dimensional objects by layering materials such as concrete, plastic, or metal. It uses computer-aided design (CAD) software to create a digital model of the object or structure, which is then translated into a physical object by the printer. In construction, 3D printing technology is used to print building components, create intricate designs, and even build entire structures.

How does 3D printing work?

Construction companies have been exploring the possibilities of 3D printing technology since the 1980s. However, advancements in the technique have led to a surge in its popularity, enabling the creation of three-dimensional objects by layering successive materials. This technique is versatile and can be used to construct specific components or even complex structures, including houses, offices, bridges, walls, modular buildings, reinforcement molds, columns, urban furniture, and decorative elements.

In the construction industry, the success of 3D printing depends on the design process. Thanks to the industry’s familiarity with computer-aided manufacturing and the growing use of Building Information Modeling (BIM), integrating 3D printing technologies has become less complicated. By using a CAD, a 3D printer can receive instructions on what to print, and machines will start layering materials accordingly. Different materials can be used, with the most common being a combination of concrete, geopolymers, fiber, and sand.

The evolution of 3D printing technology in the last decade has been remarkable. Research and Markets predicts that the value of 3D printing in the construction market will reach up to USD $1,034,096.7 thousand by 2028. This represents a compound annual growth rate of 91.5% between 2021 and 2028.

Benefits of 3D Printing in Construction

3D printing offers several advantages for the construction industry. Some of the key advantages are

Cost efficiency:

3D printing can reduce the cost of construction by cutting down on waste, transportation, and labor costs. It also allows for the use of lower-cost materials that can be printed on-site, reducing the need for expensive prefabricated components.

Environmentally friendly:

3D printing can significantly reduce the amount of waste generated during construction, as it uses only the amount of material needed to create a structure. This reduces the amount of raw materials required, resulting in lower emissions of hazardous pollution.

Time-saving:

3D printing can speed up the construction process, as it allows for the rapid production of parts and components. This reduces the amount of time required for traditional manufacturing and assembly processes, ultimately leading to faster construction times.

Reduced manpower:

3D printing can help reduce the need for manual labor in construction, as it automates much of the manufacturing and assembly process. This can lead to significant cost savings, particularly in regions where labor costs are high.

Challenges of 3D Printing in Construction

While 3D printing is a promising technology with numerous applications, it also faces several challenges that limit its widespread adoption. Some of the main challenges of 3D printing are

Conceptualization & Planning:

Designing an object for 3D printing requires a significant amount of skill and expertise. It can be challenging to translate a 2D design into a 3D model that is printable. Additionally, 3D printing requires careful planning and optimization to ensure that the object can be printed successfully and efficiently.

Cost:

3D printers and the materials used for printing can be expensive, making it difficult for individuals or small businesses to afford the technology. In addition to the cost of the printer and materials, there may be additional costs associated with post-processing and finishing the printed objects.

Limited Capabilities:

While 3D printing technology has come a long way, there are still limitations to what can be printed. Most 3D printers can only print objects with simple geometries and shapes, such as walls or basic structures. More complex objects or those with intricate details may be difficult to print.

Manual Labor for Fitting:

While 3D printing can create complex structures, it cannot create functional electrical or plumbing systems. This means that additional manual labor may be required to fit these systems into the 3D-printed structure. This can be time-consuming and costly, reducing the overall efficiency of 3D printing.

Future of 3D Printing in Construction

Despite the challenges, the potential for 3D printing technology in the construction industry is increasing. The ability to print building components, designs, and structures quickly and accurately has the potential to transform the construction industry. The future of 3D printing in construction looks promising, as more companies are adopting this technology and developing new ways to use it.

Conclusion

3D printing technology is rapidly changing the way buildings are constructed, offering numerous benefits over traditional construction methods. With the potential to save time, reduce costs, and improve accuracy, 3D printing is becoming an increasingly popular option in the construction industry. While there are still challenges to overcome, the future of 3D printing in construction looks bright, and we can expect to see more buildings constructed using this innovative technology in the years to come.